- DIAMOND USA

- Technologies

Fiber Optic Technology - transmission of information at the highest speed

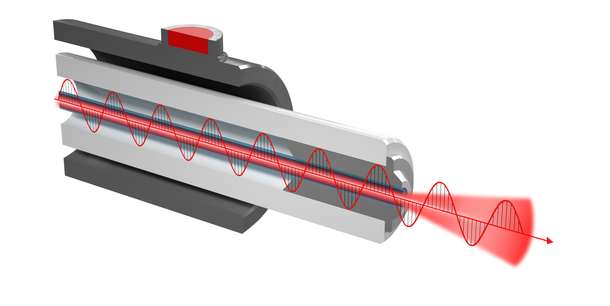

In fiber optic technology, optical fibers are used as a transmission medium for information. This information is transmitted in the form of light pulses through the fibers. This means that it is an optical transmission of signals and not an electrical one, as is the case with copper cables, for example. In this way, large amounts of data can be transported stably and over long distances. Fiber optic technology works by having laser sources generate light signals that are fed into the core of the fiber for further transmission. In order for Fiber optic Technic to develop its full potential, the accuracy of the structure and properties of the Fiber optic Patchcords and other Fiber optic Components are particularly important.

Fiber Optic Technique - Structure of a Fiber Optic Cable

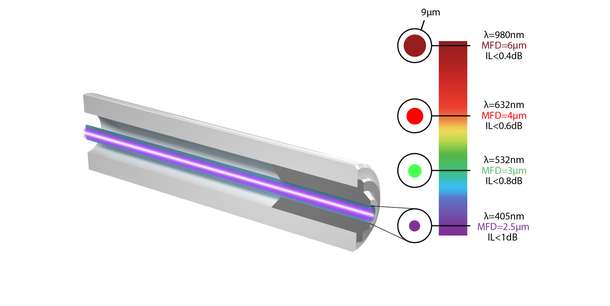

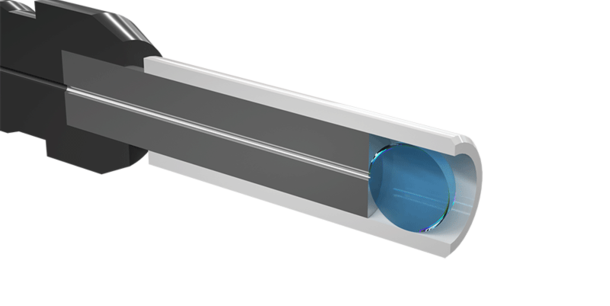

Fiber optic cables are made up of several layers which together ensure that the light signal is optimally transmitted. In the center of an optical fiber is the core, which takes over the transmission of the optical signal. It is made of silicon quartz glass and has a thickness of at least 9 µm. The second layer around the core is the inner jacket. The special feature of this glass layer is its lower refractive index compared to the core. This means that the optical signal is completely reflected at the glass transition and cannot escape. Fiber Optic technology is used in a wide variety of applications, which is why the optical fibers must not be too fragile. For this reason, the outermost layer of the Fiber optic cable, the so-called outer jacket, is made of plastic. This greatly increases the overall resilience and resistance of the cable.

Advanced opto-mechanical Fiber Optic Technology

Diamond provides a wide range of products based on advanced technology. In doing so, the company draws on its own know-how acquired during its many years of experience in manufacturing special Fiber Optic connectors that meet various customer requirements.

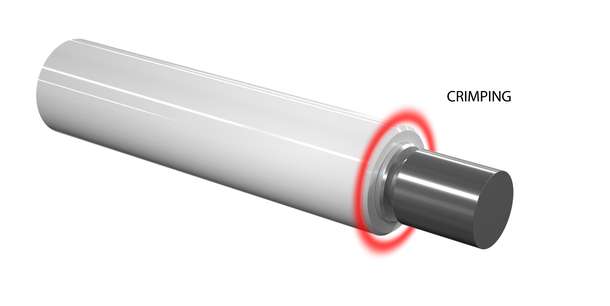

All DIAMOND technologies are based on a multi-component ferrule. DIAMOND has chosen a multi-component ferrule with a sleeve made of zirconium ceramic and an insert made of titanium.

The advantages of a multi-component ferrule:

- Allows plastic deformation for active core alignment (ACA)

- Excellent fiber centring even with small core fibers > 2.5µm

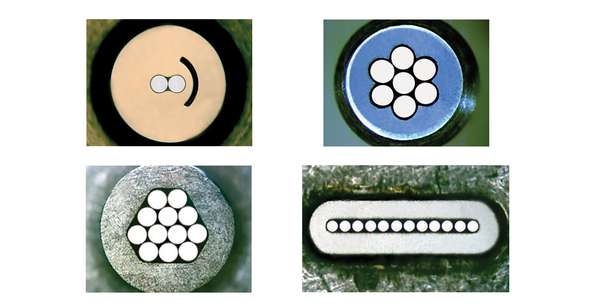

- Possibility of variable hole sizes from 80 to 800 µm

- Ultra-fine polishing

- Application-specific ferrules for multi-fiber technology

- Extremely small deviations in ferrule outer diameter